Advantages of Amorphous Metal

Energy Savings with Amorphous Metal Core Distribution Transformers

Minimizing energy loss in a Transformer holds the key to increasing the energy. With this concept as the guiding light, Vijai has set up an exclusive “state-of-the-art” manufacturing facility for the manufacture of the Amorphous Metal Distribution Transformers. For the prevention of global warming, there are many needs related to the reduction of CO2 and other greenhouse gas emissions, and the efficient use of energy and decrease of electricity use are being urged. In addition to cutting the amount of electricity used, another vital issue is reducing the power loss that occurs in transformers when electricity, coming from power plants through substations, is distributed from power plants through substations to factories, buildings and homes.

- What is Amorphous Metal?

-

The Amorphous Metal, an alloy of Fe78-B13-Si9, has non crystalline structure which is formed by cooling molten metal rapidly at cooling rates of 106 °C/sec.

The atoms do not get arranged as proper grain structure, but are arranged randomly. After annealing under a magnetic field, this alloy exhibits low losses as it gains excellent Magnetic and Chemical properties as compared to the conventional material.

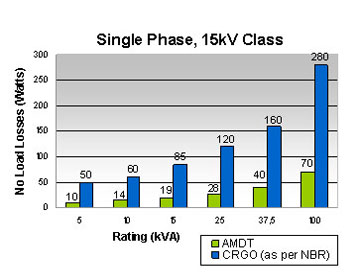

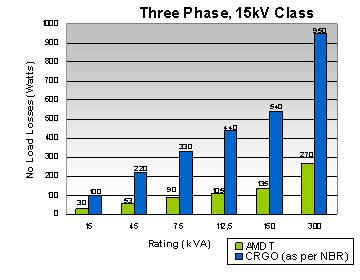

Amorphous Metal Distribution Transformers are the proven energy savers and this is because the Amorphous Metal core reduces the No load losses by about 75% when compared to the conventional CRGO grade.

- Amorphous (vs) CRGO Core Temperature Rise Factor

-

These photographs show the temperature distribution due to the core losses as observed by an infra-red camera. The Amorphous core indicates a very low temperature rise due to the low inherent core loss as compared to CRGO.

-

Amorphous Core

CRGO Core

- Advantages

-

- No-load loss are reduced by 75% as compared to CRGO transformers

- Less magnetizing current

- Cumulative saving of energy cost

- Total Owning Cost to customer in much less

- Less Temperature rise of core

- No Load Losses Comparison of Amorphous Metal Core (vs) CRGO Core (as per NBR)

Contacts

Vijai Elétrica do Brasil Ltda.

Av. das Indústrias, 400 Distrito Industrial

58.082-050 João Pessoa - PB – Brasil

Vivo: +55 (83) 9-9306-1388

Oi:+55 (83) 9-8604-4950

Tim: +55 (83) 9-9817-5228

www.vijai.com.br / marketing@vijai.com.br

- Automatic PLC based Dereeling and Spooling machines:

- Amorphous ribbons are spooled by a fully automatic system, into multi-ply run by Programmable Logic Controller (PLC’s).

-

- Automatic PLC based core cure cutting Machine:

- The multi-ply amorphous ribbons are cut to desired length automatically, run by PLC, then centered and stacked in to a pallet.

-

- Continuous Magnetic Field Annealing:

- Formed cores after core cutting are annealed in a continuous annealing furnace under magnetic field and Nitrogen atmosphere. This process is a Patented Technology of Vijai Electricals.

-

- On-line process of Oil filling under vacuum:

- The oil filling is done under vacuum by an online oil filling process.

-

- On-line Testing of Transformers:

- Apart from that section testing of components and sub-assemblies, each Transformer is tested online in the manufacturing stage. This ensures a defect free product which is perfectly reliable and gives the customer a trouble free operation.

-